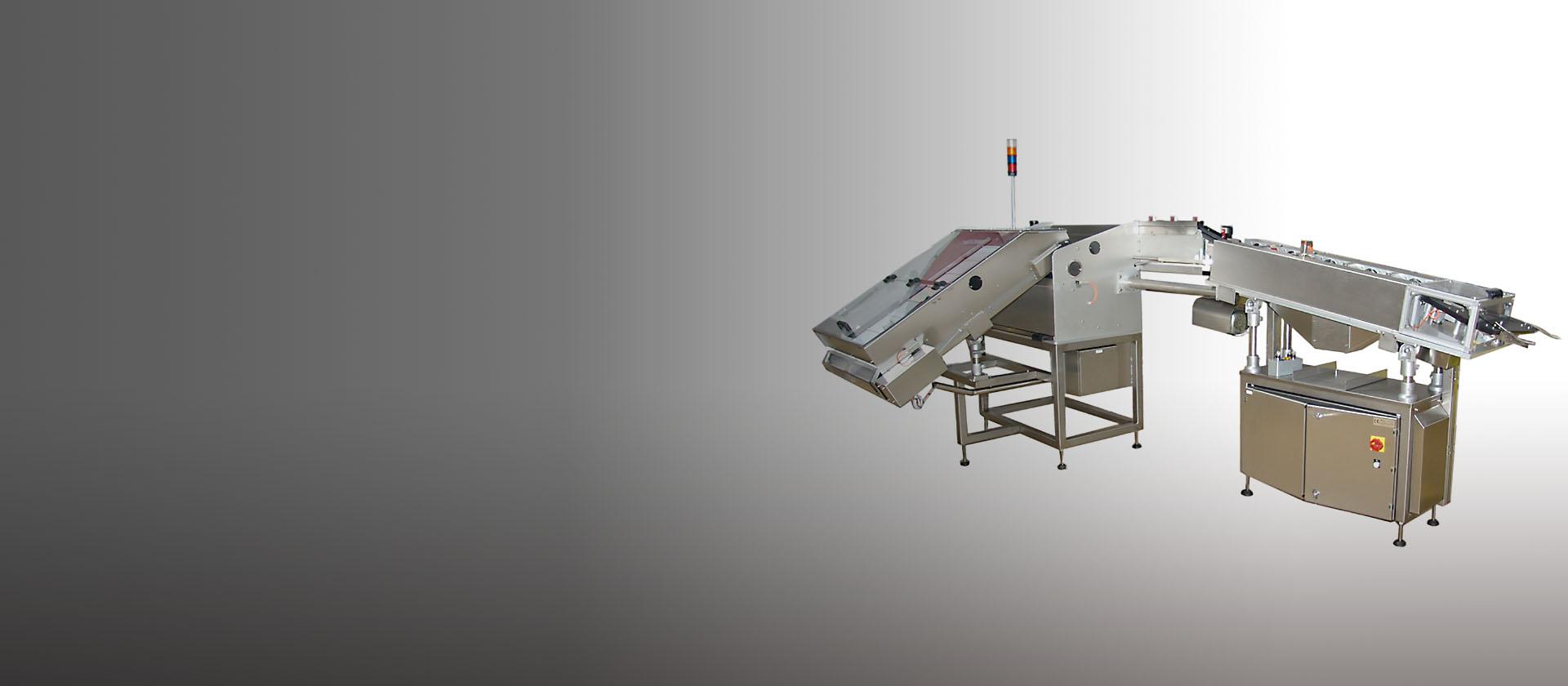

Vibrating bowl feeders for bulk material loading

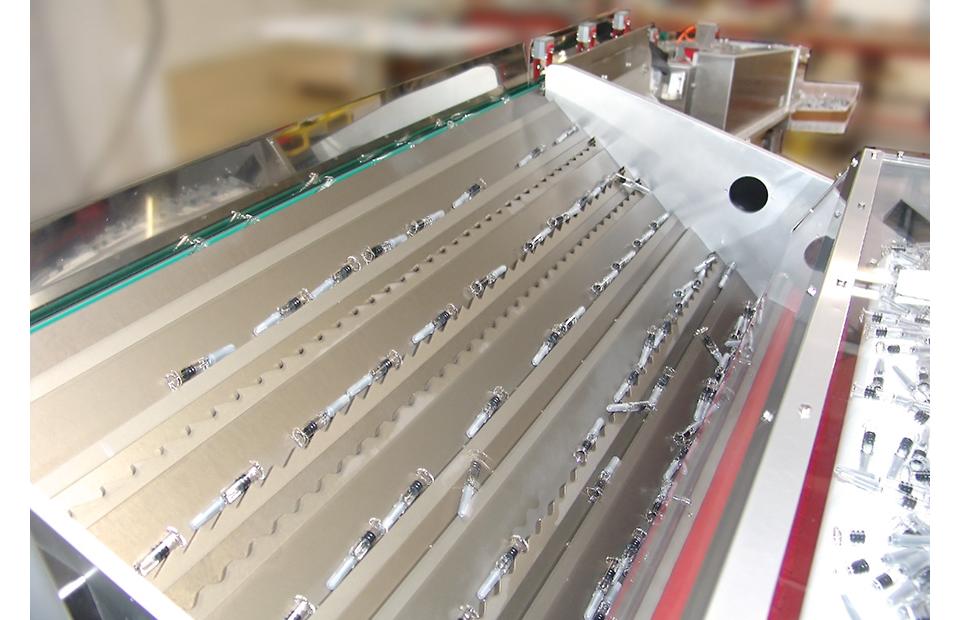

Bowl feeders are the easiest way to feed bulk material to your machines at the beginning of the line. The vibrating movement positions the units upright from the bulk. Once ready, an automatic device picks up the products from the feeder.

Vibratory bowl feeders are available with a wide range of hoppers, sizes and shapes of bowls. We select the suitable inner coating according to various criteria, such as the material of the parts, the sensitivity, or the operating speed.

Our bow feeders suit best for non-fragile plastic or metal parts or materials. Their output speed is ten to 150 parts per minute, while changeover takes only two to ten minutes, depending on the handled products.

For pharmaceutical applications, we provide specific versions with stainless steel bowl feeders, base plates and housing.